Why Galvanised Steel?

Early corrugation iron roller in the Kapunda Museum: Image courtesy of author.

One of the key developments in the history of galvanizing metal was the presentation of a research paper to the French Royal Academy in 1742 which described how iron could be protected from corrosion by dipping it into molten zinc.

The use of corrugated galvanized iron is believed to have been initially used by the Navy in Wales around 1844. By 1850 the British galvanizing industry was well established, producing 10,000 tonnes of zinc annually to protect iron products.

The hot dipping method, where the metal is dipped into molten zinc at around 450 degrees Celsius, produces a unique molecular coating which bonds to the dipped metal. This bond creates long-lasting and durable products which have become part of our everyday existence. Street light poles and barricades, gate latches and fencing, nuts and bolts – cost effective and durable galvanized steel forms the basis of our construction industries.

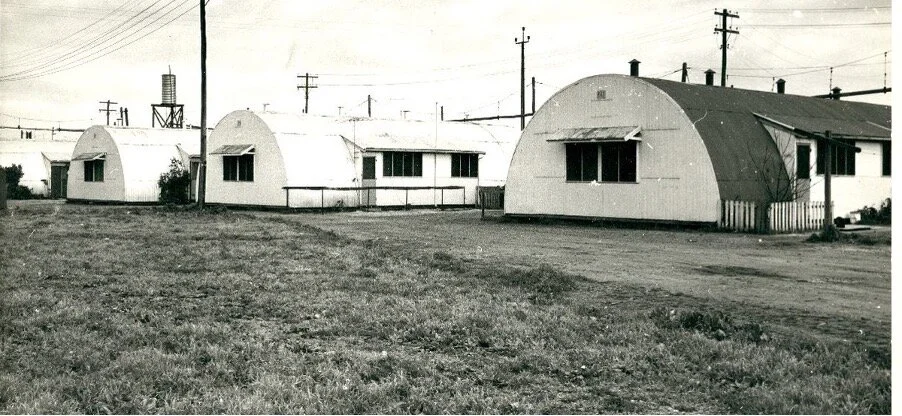

In Australia, the use of corrugated galvanized sheets for items such as water storage tanks and roofing has contributed to our cultural identity. Lightweight and easily transportable, the humble ‘galvo’ has played an important role in our urban expansion during the 20th century, particularly during the great migration period after WWII.

Gepps Cross Migrant Hostel: image courtesy of sahistoryhub.com.au

Galvanized steel has become etched in our psyche as the ideal building product for our harsh weather conditions and has continued with advancements in design found in Colorbond steel cladding products. Galvo is a good thing – and we’re sticking with it!